LET’S INVENT

MILLTRONICS USA

Tool Room Mills

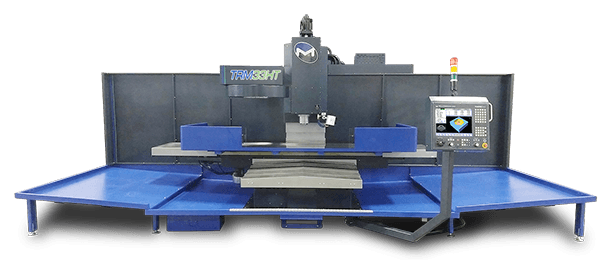

Milltronics has a long history of building tool room machines that can be run as manual, teach or full CNC with thousands of satisfied users. Popular in tool rooms, job shops, and tool & die, these machines are very flexible and can be used for a wide variety of different parts. We offer two types of quill machines in a traditional knee style (VK) as well as a bed type (TRQ). The rigid head (TRM) machines are available in four different sizes starting with a compact 30 x 16 in model up to a large travel 78 x 33 in.

The TRM3016 is a tool room mill that offers large travels, speed, and power at a great price. The TRM3016 (pictured above) has “drop down” door openings for long part pass-through to help accommodate oversize parts.

Tool Room Mill

VK4II

The VK4II is a full 3-Axis CNC knee mill with the unique Milltronics MillSlideTM that provides greater rigidity and more spindle nose to table top than conventional knee mills. With 33″ x 14.25″ x 5.25″ (MillSlideTM), 16.5″ knee and 5.83″ quill travel, the VK4II can be run as manual, teach or full CNC.

Tool Room Mill

TRM3016

The TRM3016 is a tool room mill that offers large travels, speed and power at a great price. A unique feature of the TRM Series is the “drop down” door openings that allow long part pass through to help accommodate oversize parts.

Tool Room Mill

VK4II

The VK4II is a full 3-Axis CNC knee mill with the unique Milltronics MillSlideTM that provides greater rigidity and more spindle nose to table top than conventional knee mills. With 33″ x 14.25″ x 5.25″ (MillSlideTM), 16.5″ knee and 5.83″ quill travel, the VK4II can be run as manual, teach or full CNC.

Tool Room Mill

TRQ20

The TRQ20 is designed for versatility and precision, featuring a robust Meehanite cast iron frame and heavily ribbed castings for superior dampening during high-speed machining. Its 54″ x 16″, precision-ground table is supported by hardened and ground square box ways with Turcite surfaces to maintain accuracy and eliminate deformation.

The 4.125″ quill with 6″ of travel, CT40 taper, and ±15/45 tilting head provides exceptional flexibility. A belt-driven spindle with an 8:1 back gear delivers high torque for demanding applications, while a powered drawbar ensures secure tool retention. High-precision ballscrews and belt-driven AC servo motors maximize performance and reliability, making the TRQ20 ideal for a range of machining needs.

Contact Advanced Machinery Companies and

Buy One of These Machines Today!

Our Used Machinery inventory changes daily, be sure to opt-in below for weekly email notifications.

Milltronics USA Machinery, Piranha, Hydmech, Akira-Seiki, Hexagon, Kent USA, Summit, Acu-Rite, Chevalier, Wellsaw, W.F. Wells, Newall, Dake

Contact Info

Corporate Office

4530 Wadsworth Rd. | Dayton, OH 45414

Mon-Fri, 8:00 am — 5:00 pm

Toll Free: 800-759-7337

Dayton Local: 937-278-7337

Northern Ohio: 440-354-5056

Email:

info@advancedmachinery.com

© 2026 Advanced Machinery Companies, All Rights Reserved. Site Designed by: Bertke Creative