HEXAGON Horizontal Arm CMMs

The advantages of the horizontal arm coordinate measuring machines (CMMs) from Hexagon Manufacturing Intelligence are particularly apparent when inspecting sheet metal parts in the car industry, or other large-volume components in the aerospace, ship, defense, appliance, machinery and railway industries. Their open structure permits direct access to the workpiece and therefore significantly eases loading and unloading. Horizontal CMMs can also be integrated as a component of an automated production line such as automotive body-in-white.

HEXAGON DEA TRACER

DEA TRACER – Measure and More

DEA TRACER is a manual coordinate measuring and scribing device. Its construction features a horizontal arm that is ideal for measuring and scribing medium- to large-sized parts such as design models, mould and die cores, carpentry structures or sheetmetal parts.

The mechanical structure of DEA TRACER has been optimized for easy manual motion. The horizontal arm is always balanced out, thus, users can position the arm precisely without fatigue, even after extensive use. Axis motion and locking are handled via control knobs and independent brakes for all axes. The axes slide on linear guideways and recirculating bearings that do not require air supply.

The basic model of DEA TRACER consists of a simple single-arm configuration. Also a digital readout and the HH-T probe head are part of the standard package. As an option dual arm versions, special work tables, a tracing kit and the PC-DMIS measurement software are available.

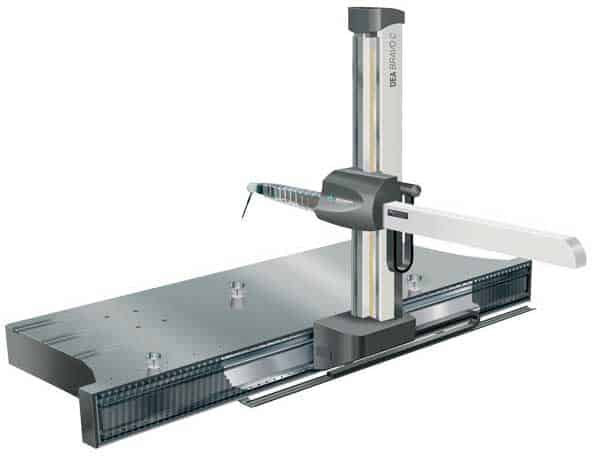

HEXAGON DEA BRAVO Console

DEA BRAVO Console – Compact, Flexible, Robust

The DEA BRAVO Console line is a technically advanced and cost-effective solution for flexible and accurate dimensional inspection of thin-walled components, ideal for mid-size parts in industrial environments.

The guideways located on the side of the machine base (Console architecture) allow the arm to be moved fully outside of the working area. For optimal access to the work area and simple part loading/unloading operations.

The cast iron machine table features the exclusive three-point support system, which eliminates the need for costly dedicated foundations, and makes the installation on vibration dampers easier.

Just like the HP and HD series, the DEA BRAVO Console line is fully made of steel, ensuring high structural stability in all environments.

Two versions are available: DEA BRAVO C and DEA BRAVO C HS (High Speed).

HEXAGON DEA BRAVO HA

DEA BRAVO HA – Car body in-process gaging

BRAVO HA is the highest performance DEA horizontal-arm measuring robot available on the market. Designed to operate in industrial environments, the BRAVO HA is the optimized answer to the dimensional inspection of car bodies and sub-assemblies in the shop floor. The exclusive design, innovative materials and advanced technical solutions enable BRAVO HA to achieve the best metrologic and dynamic performance in the harshest environmental conditions.

BRAVO HA is an advanced line of measuring and inspection robots for high-speed flexible in-process gauging of car bodies and sub-assemblies. BRAVO HA are rugged, fast and highly reliable systems designed to operate in the harshest industrial environments, for production process monitoring and control. These systems are designed to be easily integrated into the production line and can be equipped with exclusive high-speed non-contact measuring heads that allow inspecting sheet metal features in 1/10 of the time currently needed with conventional probing systems.

Due to the modular open structure BRAVO HA can be easily integrated into the production line and configured in multi-arm cells that combine the flexibility and ease of programming of CMMs with the speed and user friendliness of conventional measuring gauges. The combination of several original design solutions makes BRAVO HA extremely stable, stiff and resistant to the harsh shop floor conditions. Maximum speed of 52 m/min, acceleration of up to 2.9 m/s2and FLY axis interpolation make BRAVO HA one of the most efficient body-in-white robots in the market.

HEXAGON DEA BRAVO HD

DEA BRAVO HD – The heavy duty horizontal arm CMM

The BRAVO HD is a technically advanced and cost-effective solution for flexible and accurate dimensional inspection of thin-walled components like bodies-in-white and their subassemblies. BRAVO HD belongs to the BRAVO line which also includes BRAVO HP and BRAVO HA. It utilizes a stable, precise mechanical structure, an integrated temperature compensation system, a wide range of probes, probe heads, wrists and accessories and a state-of-the-art software package, delivering an effective coordinate measuring machine that is particularly well suited for operation in metrology labs, QC rooms and Meisterbock rooms.

Just like the HP Series, the BRAVO HD is fully made of steel, ensuring high structural stability in all environments. All axes use recirculating ball-bearing pads sliding on high-precision guideways. The innovative backlash-free horizontal-arm counterbalance keeps the load centered on the mobile carriage and reduces the mechanical deformations of the carriage itself. The open structure can be embedded flush with the floor. The walkable covers on the longitudinal axes guarantee optimum access to the measuring area and simplify loading and unloading of parts as well as programming and automatic dimensional inspection.

The system equipment of the BRAVO generation is complemented by a wide range of non-contact and tactile electronic probes and integrated tool racks. Continuous wrists and indexable probe heads accept extra-long extensions and automatically orient the measuring sensor to any position, thus optimizing the dimensional inspection cycles of the most complex sheet metal artifacts.

HEXAGON DEA BRAVO HP

DEA BRAVO HP – Sheet metal inspection at its best

The BRAVO HP has been designed to meet in an optimum way the requirements of dimensional inspection and analysis of bodyshells, chassis and subassemblies on the shop floor. It is characterized by high dynamics and accuracy. BRAVO HP belongs to the BRAVO line which also includes BRAVO HD and BRAVO HA. The stable, precise mechanical structure, the integrated temperature compensation system, a wide range of probes, probe heads, wrists and accessories as well as a state-of-the-art software package make it an effective CMM that is particularly well suited for operation in shop-floor environments, metrology labs and QC rooms.

BRAVO HP is an automatic horizontal-arm system characterized by high performance, designed to optimally tackle a wide variety of metrology applications in the production environment. It is an advanced system offering a consistent and efficient approach to car-body inspection and integrates innovative industrial measurement technologies into single- and double-arm horizontal structures. It is the perfect combination of performance, accuracy, flexibility, dependability and user-friendliness. The open structure of these measuring systems, which can be installed flush to the floor, and the walkable covers along the longitudinal axes ensure the maximum ease of access to the measurement area, thus, simplifying the part loading and unloading operations, programming and automatic dimensional inspection.

HEXAGON DEA MERCURY

DEA MERCURY – A flexible trio

DEA MERCURY stands for three different versions of horizontal-arm coordinate measuring machines (CMM). All of them are based on a modular concept. Automatic machines, disengageable drives for manual operations, single-, dual- or multiple-arm-configurations, tactile probes, optical sensors, scribing devices, fixtures…You name it. The DEA MERCURY line offers it.

DEA MERCURY’s outstanding price performance ratio is especially attractive for companies with limited budgets. Thanks to its modularity this CMM line is suitable for rebuilding existing installations which require a technological update. To make previous investments really pay off.

HEXAGON DEA TORO

DEA TORO – The cost-effective Runway type horizontal arm CMM

The DEA TORO is an innovative line of automatic horizontal arm measuring machines for dimensional inspection of sheet metal components and large size parts. TORO features an extraordinary price/performance ratio and is available in the Runway structure with the main guideway fixed to the floor.

The measuring machines of the TORO series can be employed as metrology stations in the development and engineering departments for supporting industrial design of complex contoured shapes, as well as flexible gages for process control in a shop environment.

The TORO series is available in the Runway type architecture. That means that the main guideway is floor-mounted. It is extremely modular and easy to configure, thus, combining flexibility and programmability that are typical of CMMs, with the speed and intuitive use of traditional measuring gages.

Contact Advanced Machinery Companies for Additional Information

Our Used Machinery inventory changes daily,

be sure to opt-in below for weekly email notifications.

Contact Info

Corporate Office

4530 Wadsworth Rd.

Dayton, OH 45414

Mon-Fri, 8:00 am — 5:00 pm

Toll Free: 800-759-7337

Dayton Local: 937-278-7337

Northern Ohio: 440-354-5056

Email:

info@advancedmachinery.com

© 2024 Advanced Machinery Companies, All Rights Reserved. Site Designed by: Bertke Creative